A necessary evil for any producer in the wine, brewery and beverage industry is Tank cleaning. It is required between batches to ensure a reliable, uncontaminated, quality batch is produced and consumers get the same great tasting product each time.

The cleaning process not only requires a considerable amount of chemicals, water, labour and electricity but also time. Particularly when a cycle is required to be re-run as cleaning was not sufficient the first time round. The cost associated with cleaning can have a significant effect on the bottom line. Currently producers still tend to rely on outdated processing for cleaning, not realizing the potential opportunity for cost reductions, production increase and revenue recovery through clean in place optimization.

Before one can optimise the cleaning process, one should first grapple the basics of cleaning. Herbert Sinner first summarized the basic principles of cleaning in 1959 as a chemical engineer for Henkel. His summary, now referred to as the Sinner’s Circle (Seen Figure 1), describes the four basic factors that can be manipulated in any cleaning scenario: Temperature, Chemical Action, Mechanical Force and Time.

Figure 1: Sinner’s Circle

If a single one of the above factors is reduced it needs to be compensated with an increase in one or multiple of the other factors. A great example everyone can relate to is washing dishes. The hotter the washing water (temperature) the better it will remove stuck food and fats compared to cold water. Soaking the dishes (Time) always reduces the amount of scrubbing (Mechanical Force) required, and naturally adding more soap (Chemical Action) to the water always improves the effectiveness.

A critical point to consider when evaluating a CIP system is not only the effectiveness but also the efficiency of the process. Considering each variable, in ones control, within the four categories allows a production manager to find an optimum cost effective system.

The most common tank cleaning processes are: wetting (typically using archaic static spray balls, see Figure 2), rotary wetting (reaction-force driven), boiling out, manual cleaning and rotary impingement cleaning (high impact jets turbine driven).

Rotary wetting and wetting are more easily understood as a “cascading method”. By applying the cleaning solution to the tank interior, the residue eventually erodes off with moderate impingement provided pressures are, counterintuitively, kept low (2-3.5 bar). Higher pressure typically result in a smaller droplet size and subsequently less travel and impact of the droplets on the tank sides. Boiling out, is typically not used from a time and water consumption perspective, and has no mechanical action. Manual cleaning on the other hand, provides a reasonable amount of mechanical force, with minimal effluent but can result in ineffective cleaning, due to human error (never mind the time consumption for lock out/tag out in bigger installations).

Rotary impingement cleaning, utilizes the most mechanical force than any other process, however is sometimes not preferred due to the small passages and intricacies of the nozzles themselves.

A critical part in any CIP process, and one of the most overlooked, is the selection of the nozzle performing the spraying in the tank. It is overlooked as the cost of the nozzle is insignificant compared to the overall cost of the system, however, often it has the biggest effect on the effectiveness and efficiency of the system.

As the majority of existing systems still utilize the old spray ball (see Figure 2) operators often have the following frustrations:

- Clogging

- Extended maintenance time

- Incomplete tank coverage

Furthermore static nozzles do not rotate and therefore require a large amount of cleaning fluid compared to the other two styles. However, because they have no moving components, static nozzles may provide a longer service life.

Figure 2: Archaic Spray ball

Reaction-force driven nozzles use spinning heads that rotate from the force of the cleaning liquid leaving the head. Reactionary-force driven nozzles are very efficient and use comparatively a much smaller amount of cleaning fluid than static nozzles. Some reactionary-force nozzles are free-spinning while others rotate much more slowly. Examples of reactionary-force driven nozzles are the BETE HyrdroWhirl® Poseidon® and HydroWhirl® S as seen in Figure 3.

Figure 3: Left: HydroWhirl Poseidon, Right: HydroWhirl S

Turbine driven nozzles use the cleaning liquid to drive an internal turbine which rotates the nozzle at a controlled speed. Turbine-driven nozzles often use an impingement jet rather than a fan spray and are useful for large tanks and for cleaning difficult residues such as peanut butter, BBQ sauce, paint, and etc. Examples of theses nozzles are the BETE HydroWhirl Orbiter and the little brother the HydroWhirl Orbiter 100 as seen in Figure 4.

Figure 4: Left: HydroWhirl Orbitor, Right: Smaller HydroWhirl Orbitor 100

Traditionally impingement jet cleaners have been seen as being necessary only for larger tanks or heavy residues. For very big tanks they are the only viable option as only jet cleaners have the necessary reach. With tough residues the time it will take for low impact cleaners to break down the residue make them inefficient both in terms of water used and down time on the process vessel so, again, impingement cleaners are the only viable option.

As they were primarily aimed at cleaning large tanks with tough residues impingement cleaners have typically been geared to rotate quite slowly. The slow motion gives the cleaning jets enough dwell time to really act on heavily soiled tank walls. This slower motion, coupled with the hard lower limit on time due to set cleaning cycles, means that most impingement cleaners have been inefficient for small tanks or lighter residues. However, a new breed of fast cycle impingement cleaners is promising to change that.

For smaller tanks with lighter residues a fast cycle jet cleaner (FCJC) can save considerable amounts of time and water. The amount of water savings will depend on tank size and the time a traditional spray ball would need to be operation to achieve cleaning.

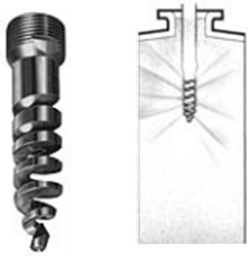

Important factors to consider when selecting a nozzle are: tank size, mounting location, pressure, flow rate, cleaning medium, residue to be cleaned, opening size, drain size. For instance if the size of the opening is a constraint the TW nozzle as seen in Figure 5. This nozzle is specifically designed to be narrow in profile with its clog-resistant spiral design.

Figure 5: TW Nozzle

Tank size

As tanks increase in size they require larger flow rate spray balls to rinse them. The reach of static nozzles depends very much on the amount of fluid going through them. Also the cleaning is performed by a fluid flowing down the walls of the tank a certain volume of fluid is required to achieve the necessary cascading. All this means that as tank diameter increases the flow through spray balls increase dramatically. The same is not true for impingement cleaners. Even small 3mm nozzle machines running at low pressures achieving cleaning jet length of several meters.

For sub 1 meter diameter tanks small spray balls will low flow rates will typically be sufficient. As such even the new fast cycle impingement cleaners may struggle to be beat static nozzles on efficiency. Even so for tougher residues that would require a cleaning cycle of over 20 minutes using static cleaners, the rotary jet cleaners may still be more water efficient and will certainly do the job quicker. As an example fast cycle jet cleaners running at low pressures (3 bar) can complete a cycle in about 6 minutes or under 3 minutes at higher (10 bar pressure).

As tank size increase the benefits of the faster cycle jet cleaners increased exponentially. For tanks in the 2 meter diameter range rotary jet cleaners will almost always be significantly more water efficient than static cleaners. Only very light residues that require a sub 5 minute clean with static spray balls would not be suitable for fast cycle jet cleaners (FCJC). Much above 3 meters in diameter and static spray balls will always use more water than FCJC’s and with anything above 5 meters will normally be out of range for spray balls anyway.

Residue type

Other than tank size the residue type is the biggest factor when determining the amount of cleaning power required. As noted at the beginning of this article static spray balls will break down tough residues eventually but require time to do so. Of course for tougher residues this mean that static spray balls become more and more water thirsty. When tough residues are combined with larger tank sizes the overall water consumption per cycle by static cleaners can get very large indeed.

In contrast even small nozzle impingement cleaners at low pressures can blast through tough residues. Of course higher pressures are always advisable for sticky and heavily soiled tanks. What this means is that where a static nozzle may take 20 minutes to achieve cleaning an impingement cleaner will do the job in a single cleaning cycle which can be well under 5 minutes. Additionally as the flow rates are typically lower through impingement cleaners so not only is time saved by water per minute is saved also resulting in potentially huge efficiency gains.

How big are the savings?

The short answer is “it depend on the tank and residue” the longer and more useful article is best illustrated with some examples.

Example 1

A 2 meter diameter tank with a moderate residue that needs a ½” BSP spray ball to run for 15 minutes to clean thoroughly. A typical flow rate at 2 bar pressure for such a spray ball would be 127 litres per minute meaning 1905 litres is required for cleaning. In contrast a 4x 3mm nozzle FCJC running at 8 bar pressure would consume 78 litres per minute and complete its cycle in about 3.2 minutes meaning cleaning is completed with 250 litres. So that’s nearly 1/8th the water and 4.7 times as fast. So even if the FCJC had to go through 2 or even 3 cycles it would still be vastly more efficient. Given that it is running at 8 bar it is likely that a moderate residue would be cleaned with just a single cycle.

Example 2

A 4 meter diameter tank that has a light residue. This is washed down on a 10 minute cleaning cycle with a ¾” spray ball running at 2 bar. This has a flow rate of 310 l/min so cleaning requires 3100 litres. In contrast a 4mm nozzle jet cleaner running at only 3 bar pressure could go through a cycle in 5.5 minutes consuming 67 litres per minute for a total water per cycle figure of only 369 litres. This is over an 8 fold reduction in water consumption and the cleaning is completed nearly twice as fast.

Latest Development: A nozzle designed for the Wine and Beer Industry

A premier winery in Napa Valley contacted BETE to help improve their tank cleaning process.

They had tried both rotating tank wash machines and traditional static spray balls but they weren’t completely satisfied with either option. Even with a preliminary rinse before the cleaning process, leftover grape debris in the fermentation tanks such as seeds, stems, and skins had a habit of finding its way into the nozzles during recirculation cleaning cycles.

BETE engineers went to work to develop a solution to this issue that plagues not only the winemaking industry but also brewing, food processing, and many other applications that involve cleaning tanks with high solids content. The result was the new HydroClaw™ nozzle with a full 360 degree spray pattern, three times the free passage of a comparable static spray ball, and no moving parts to jam.

Figure 6: The NEW HydroClaw™

The solids in the fermentation tanks would jam rotating tank wash nozzles, resulting in incomplete coverage which is detrimental to the winemaking process and difficult to detect from outside of the tank. Static spray balls, on the other hand, have no moving parts but feature many small orifices that are prone to plugging, also resulting in incomplete coverage. With both options, the amount of maintenance time required to keep the nozzles in proper working condition was unacceptable.

After trialling the unit, the customer was so pleased with the cleaning performance and clog resistance of the HydroClaw™ that they used it exclusively to clean their tanks during the busy harvest crush season, the time when the fermentation tanks experience their highest levels of solids. Over the course of several months, not a single clogging issue was experienced. Additionally, the high flow rate of the HydroClaw™ allowed the customer to adequately pre‐rinse their tanks using quick and powerful blasts of water thus reducing their overall water consumption compared to a lower flowing nozzle operating for a longer period of time. This last fact of a saving in water consumption is of particular importance in the South African Context and current water shortages.

HydroClaw advantages:

- 3X the free passage of static spray ball

- 360 degree coverage with no moving parts

- High flow rate provides vigorous rinsing action to quickly flush tank solids and contamination

- Sanitary finish for food and beverage applications

- Saves you time AND money!

Conclusions

When it comes to tank cleaning there is no one size fits all solution. However, with some thought and talking to the nozzle experts there may be considerable savings to be made. Not only very large water savings but considerable time savings.

By Karl Loubser 011 466 2100

SPRAY NOZZLE (PTY) LTD