Multi-fluid nozzles have many unique spray properties. A wide range of devices, from the simple twin fluid nozzle (providing a combination of compressed air and a liquid) to nozzles with up to four different fluids can be supplied for special applications.

The air atomising process

The break up mechanism for direct pressure nozzles is either process liquid impinging on a surface/deflector, or the liquid is forced through by increasing the pressure and reducing the orifice size.

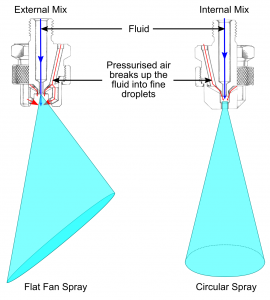

With air atomising nozzles, the break up mechanism is pressurised air/gas mixed with process liquid, to disperse it into very fine droplets. Depending on the outlet design of the nozzle, this resulting high velocity spray will have either a flat, hollow, or full cone spray pattern.

There are generally two types of outlet design available – internal mix and external mix set-ups.

Controlled spraying

Liquid and air pressure ratios are very important to the size of the resulting droplet size. Pressurised air allows for greater control over the spray. Varying this will allow for change in the shape and degree of atomization without influencing fluid pressure.

Some applications require additional control such as automatic, non-drip or high-speed spray shut-off. This can be achieved with an optional air cylinder with shut-off or clean-out/shut-off configuration. Where space is an issue, nozzle bodies are available with an integral air-operated cylinder, providing a smaller profile.

Air atomising nozzle variants

Details on the different types of air atomising nozzle produced can be found in these links to our suppliers’ websites: